Recommended helper for rolling oil treatment in industrial cold-rolled steel mills: backwash filter

Release time:

2021-04-14

The 20-roll mill is currently the main equipment used in stainless steel cold rolling. After the rolling oil, which plays a cooling and lubricating role, passes through the cold rolling process, the impurities in it are generally granular fine particles. If not removed, the rolling oil will be damaged. The oil becomes dirty and shortens the service life of the rolling oil.

20-roll rolling mill is the main equipment used in stainless steel cold rolling, in which the rolling oil that plays a cooling and lubrication role after the cold rolling process, the impurities inside are generally granular fine particles, if not removed, the rolling oil will become dirty, and lead to a shortened service life of the rolling oil.

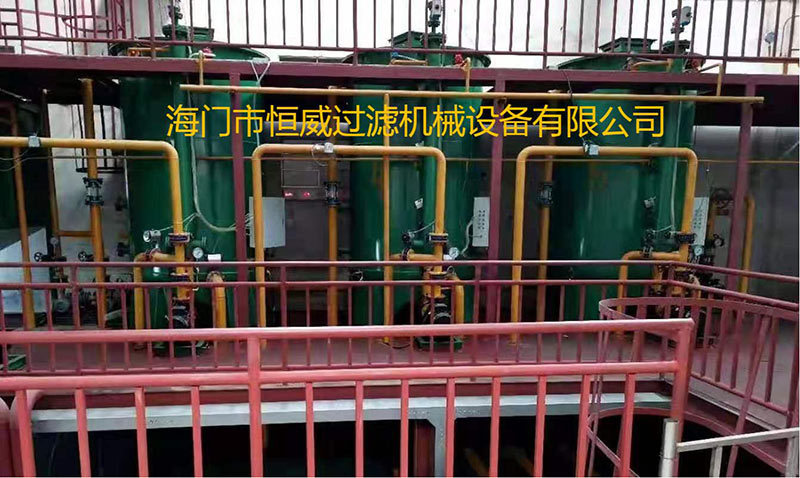

The advent of stainless steel rolling oil cooling lubrication backwash filter has greatly improved the purification function of rolling oil, and the color of the filtered oil is clear, which is different from the traditional filter. The rolling oil filtration cycle control of the main filter tank group realizes the automatic backwashing function of the filter element in the tank. The secondary filter tank backwash function is also available, and the filter element is blown back through the inner cavity of the compressed air filter disc to classify and filter it. The level gauge control installed in the dirty oil tank and the clean oil tank realizes the automatic filtration work control of the system. The backwash filter has a large amount of dirt, is not easy to be blocked, the filter part can be automatically removed, no need to disassemble and wash, so as to achieve the purpose of reducing energy consumption and extending the service life of the equipment, etc., in recent years has been strongly sought after by customers.

The backwash filter is specifically designed to filter rolled oil and is capable of automatic blowdown. At present, this filter has received a lot of attention. It has great advantages in the purification of rolling oil, and its efficient function of keeping rolling oil clean has been unanimously recognized by users.

The backwash filter can provide uninterrupted cleaning of sewage during the filtration process, easily realize the monitoring of the working state of filtration, and the degree of automation is very high, it breaks through the original tradition of structural design, overcomes the shortcomings of traditional filters, and truly realizes humanized remote monitoring and operation. It is in line with the technical requirements of the direction of modern social development.

Backwash filters rely on their unique talent and efficient features to gain a niche in the roll mill filtration market.

Previous Page

Previous Page

Latest News

Contact Information

Fax: 0513-82608508

Address: 1766 Hong Kong Road, Haimen District, Nantong City, Jiangsu Province

sweep, mobile phone official website!